Our CONCEPT team will be happy to take charge of the mechanical and electrical overhaul of your system solution, starting with an inventory, the generation of a sensible modernization concept and the time and cost-optimized implementation on site – naturally in close consultation with the customer.

This includes conversions, extensions, modifications, relocations, type retrofits based on existing machines and systems in the sense of a sustainable re-use concept. New machines and systems are designed by CONCEPT from the outset in such a way that they can be reused by the customer for subsequent projects.

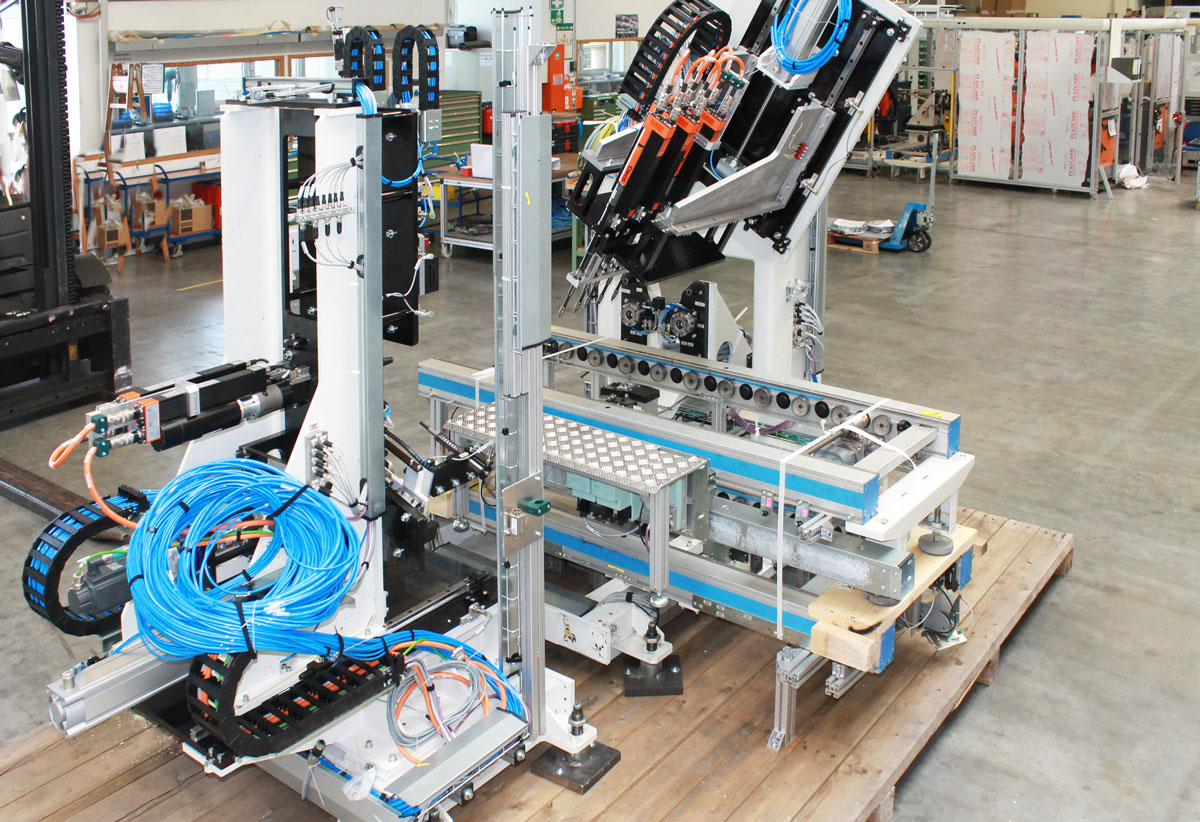

Retrofitting begins in the project planning and development phase and continues in the actual implementation phase right through to production readiness. Retrofitting orders cover all areas: Mechanical design, electrical design in HW planning and SW development as well as production and the actual conversion phase for mechanics, electrics and software commissioning.

We guarantee short downtimes during ongoing production with cost-effective implementation. With the help of virtual commissioning based on a digital twin, conversion times can be reduced to a minimum.

The advantages are obvious, including